– If you have any question pls do not hesitate to contact us. We can supply all kind of the automation parts,

-If you want to purchase parts pls send the parts model to my mail.(Email:sales7@saulplc.com)

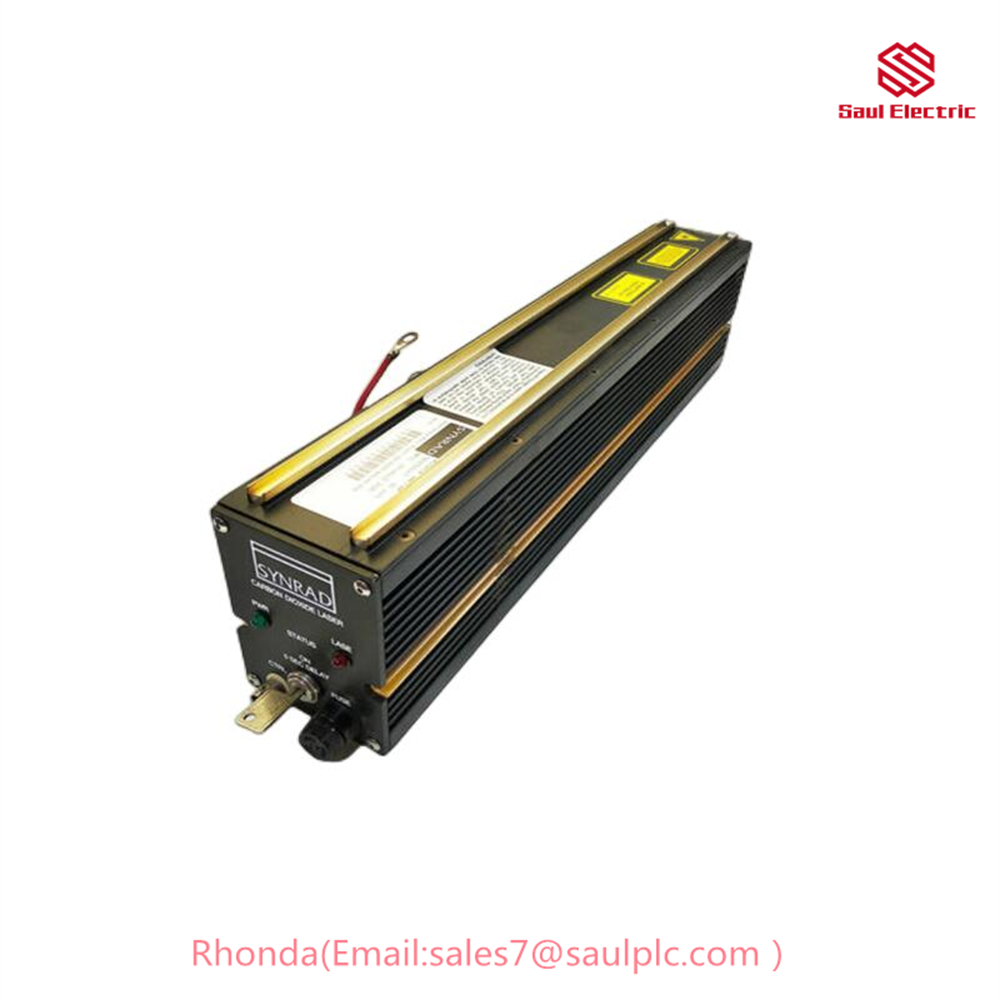

SYNRAD H48-1-28-4752 LASER TESTED

CO2 laser is a type of molecular laser that mainly uses CO2 gas molecules, with a wavelength of 10.6um, and belongs to the infrared band thermal laser.

Common CO2 lasers are divided into two types: glass tube CO2 lasers and metal RF tube CO2 lasers

Glass tube CO2 lasers are usually made of hard glass material and have a three-layer structure, divided into an inner and outer three-layer cavity. The innermost layer is a discharge tube, the middle layer is a water-cooled layer, and the outermost layer is a gas storage layer. The length of the discharge tube is related to power to a certain extent. Generally speaking, the larger the output power, the longer the discharge tube is required, which is proportional to power. The discharge tube has small holes at both ends that are connected to the gas storage tube, During operation, CO2 gas can circulate between the discharge tube and the gas storage tube, allowing for timely exchange of gases.

The metal RF tube CO2 laser adopts a sealed off type CO2 laser. The so-called sealed off type CO2 laser refers to the laser’s through-hole (i.e. the place where plasma is formed and laser is generated) and the working gas being sealed in the same tube. It is different from the flow gas laser system with higher output power, which requires an additional gas tank, The gas pump and filter. Synrad’s laser adopts an all metal structure for the first time. Its laser tube and electrode are formed by pressing aluminum and then welding. This structural design has the advantages of low manufacturing cost, long-term stability and reliability, and is also the earliest metal tube laser.

The commonly used laser tubes for CO2 laser marking machines are divided into glass tubes and metal RF tubes, and the difference between the two is:

1. Metal RF tube lasers have a small and compact volume, while glass tubes have a relatively long volume.

2. Service life: The CO2 RF tube laser marking machine has a service life of over 45000 hours, and can generally be used for 6 years. It is inflatable and can be reused without replacement; And the glass tube marking machine only takes about 2500 hours. Generally, glass tubes need to be replaced frequently within six months and cannot be reused. RF tubes can be reused

3. Cooling method: Within 100 watts of CO2 RF tube excitation, air cooling can be used, while CO2 glass tube excitation requires water cooling.

4. Spot size (beam): The CO2 RF tube laser marking machine is 0.07mm, with a fine spot that is more than three times finer than the glass tube, high accuracy, small thermal diffusion area, and can carve/cut very fine works;

The CO2 glass tube laser marking machine is 0 25mm thick light spot, poor accuracy, unstable light output (uneven light intensity, sometimes no light output), large thermal diffusion area, obvious edge melting and blackening, and poor carving accuracy. You can know which effect you can accept by actually making a sample;

5. Stability: The RF tube is a fully sealed metal tube that uses a 30 volt low-voltage power supply, which directly avoids some of the drawbacks of using a high-voltage power supply; Due to the fact that domestic glass tube laser cutting machines use a high-voltage power supply of 10000 volts or even higher, in addition to being unstable, there is also a certain degree of danger. Long term operation can easily age the power supply and cause significant interference to the control system. Improper operation can easily burn out the motherboard, making it more susceptible to the influence of voltage and damaging its normal function.

6. Price: RF tube lasers with the same power are many times more expensive than glass tube lasers, but in order to achieve the same effect, the power requirement of RF tubes is much smaller than that of glass tubes. However, even so, RF tube machines are still much more expensive than glass tube machines. So when choosing a machine, you need to choose which one to use based on your actual needs.

1、 Characteristics of metal tube RF lasers:

At present, there are three leading suppliers of closed metal CO2 lasers in terms of production and scale: Rofin in Germany, Coherent in the United States, and Synrad in the world.

2. RF excited CO2 laser is a revolution in laser design and production, with compact size and powerful functionality. It adopts a switch power supply for direct current power supply, without the need for dangerous high voltage electricity.

3. Adopting a metal sealed and completely maintenance free design, the laser gas can work continuously for more than 20000 hours, making it a sturdy, durable, and highly reliable industrial laser source. It can be easily installed on a workbench or small processing machine, and has stronger processing capabilities than traditional gas flow lasers. After replacing the gas, it can be reused for at least 20000 hours, with an overall lifespan of over 60000 hours.

4. The laser’s spot mode has good quality, high peak power, short pulse rise time, and high pulse modulation frequency, which is crucial for material processing and effectively improves the efficiency and accuracy of material processing. The spot can generally achieve fundamental mode output, which can be used to obtain very small spot after beam expansion and focusing, making better use of it in processing.

5. The laser is very stable, and the laser energy remains consistent during long-term operation, ensuring precision machining. If every laser equipment manufacturer, like the majority of lasers, seals the laser path, the front output mirror of the RF laser will never be damaged, so that the laser can work in poor environments without worrying about errors. However, this type of laser is relatively expensive.

Characteristics of CO2 sealed off glass tube laser.

1. Using glass as its working shell, it is prone to cracking or bursting due to heat or vibration, posing a safety hazard during operation.

2. This is a traditional gas flow laser with a large volume, high energy consumption, and unsatisfactory functionality, requiring the use of a high-voltage power supply. Under certain conditions, high-voltage can ignite and cause poor contact, increasing the occurrence of irregularities.

3. Short lifespan, with a theoretical lifespan of 1000 hours and a decrease in laser energy every day, it is difficult to ensure consistency in product processing and air exchange is not allowed. The laser tube needs to be replaced within 1000 hours. Replacing laser tubes is frequent and troublesome, resulting in some production orders not being delivered on time.

4. The laser mode quality is not as good as that of metal laser tubes, with low peak power and low pulse modulation frequency, which are crucial for material processing. The laser performance is also not as good as that of metal laser tubes, and cannot effectively improve the efficiency, accuracy, and effectiveness of material processing.

There are no reviews yet.