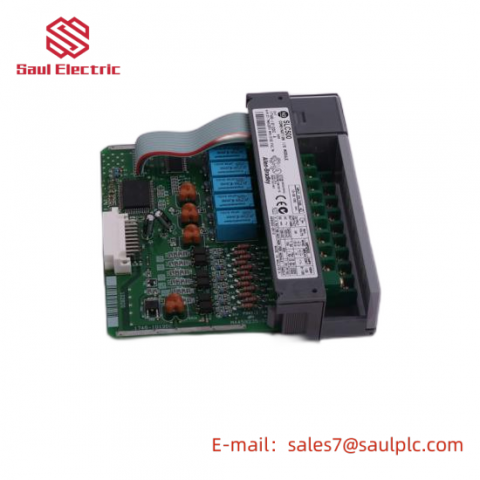

Manufacturer:AB

Model:1771-QD

Application:Injection Control

Technology:Modbus TCP/IP

Operating Range:0-10V DC

Communication Speed:10/100 Mbps

Power Consumption:5W

Dimensions:139mm x 100mm x 91mm

Operating Temperature:-20°C to 60°C

Reliability Rating:NEMA 12 Rated

Input Output:24V DC, 5V, 2x Serial Interface, 3x Free Slot

The Allen-Bradley 1771-QD Injection Control Module is engineered to integrate seamlessly into existing industrial control systems, offering advanced control algorithms for optimized performance. This module is specifically designed to manage the speed, pressure, and flow rate in injection molding machines, ensuring consistent quality and reducing waste.

With its high-resolution digital display and intuitive interface, the module allows operators to monitor critical process parameters in real-time, facilitating quick adjustments and minimizing downtime. The robust design withstands harsh industrial environments, ensuring reliability even under extreme conditions.

Featuring a versatile communication protocol, the 1771-QD can easily connect to various PLC systems, providing seamless integration and data exchange. This compatibility simplifies the setup and maintenance process, making it an ideal choice for a wide range of manufacturing industries.

The energy-efficient design of this module contributes to lower operational costs, thanks to its optimized power consumption. It’s equipped with safety features to prevent electrical hazards and ensure operator safety, complying with international safety standards.

Designed with user convenience in mind, the Allen-Bradley 1771-QD Injection Control Module comes with comprehensive documentation and online resources, offering extensive support for installation, configuration, and troubleshooting. Its modular construction facilitates easy maintenance and upgrades, ensuring long-term operational efficiency.

There are no reviews yet.