Technical Parameter

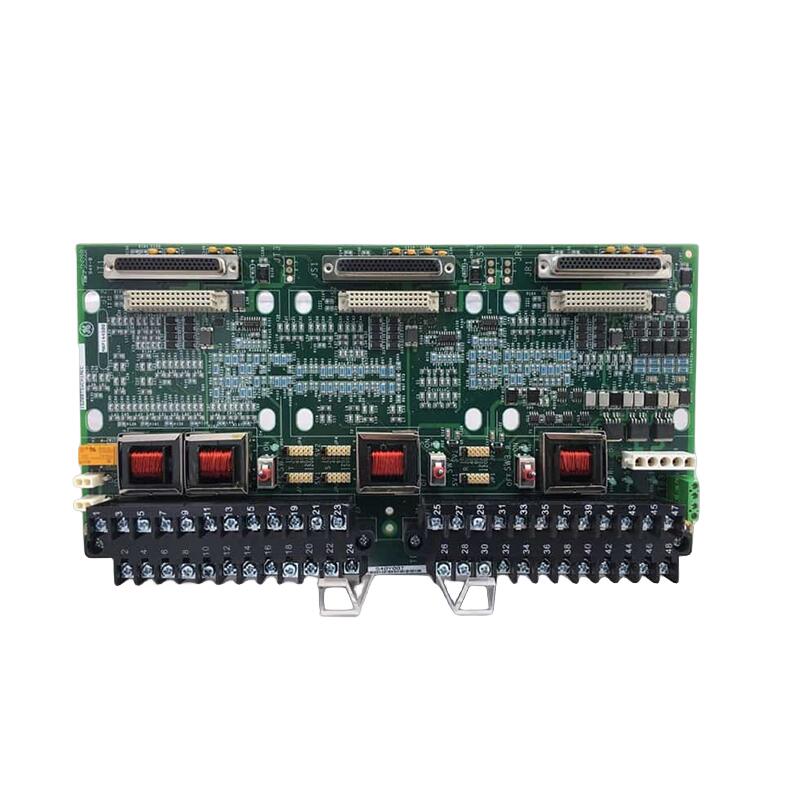

GE VMIVME-5565-010000 332-015565-010000P: High-Performance Embedded Processing Module

The GE VMIVME-5565-010000 332-015565-010000P is a high-performance embedded processing module based on the VME bus. It is specifically designed for demanding applications in industrial automation, military, and aerospace sectors.

Product Name and Model

The GE VMIVME-5565-010000 332-015565-010000P is a high-performance embedded module developed by General Electric (GE). It is part of the VMIVME series, ideal for real-time distributed systems requiring efficient data transmission and processing.

Key Features

-

Reflective Memory: The module utilizes reflective memory technology, allowing real-time data sharing between multiple nodes. It is known for its high reliability and low latency.

-

High-Speed Data Transfer: The module supports serial connection speeds up to 2.1 Gbps and can dynamically adjust packet sizes ranging from 4 bytes to 64 bytes.

-

Node Management and Error Detection: It supports up to 256 connected nodes and includes built-in error management and data integrity checking mechanisms to ensure reliable data transmission.

Hardware Specifications

-

Processor: Powered by either a PowerPC 604+ or PowerPC 750GX processor, with clock speeds of 1.2 GHz or 1.0 GHz.

-

Memory: Comes with 64MB or 128MB of onboard SDRAM, and supports DDR SDRAM and NOR Flash memory.

-

Communication Interfaces: Complies with the VMEbus standard and is also compatible with PCI, PMC, and CompactFlash interfaces.

-

Size and Weight: The module has a standard VME6U form factor, weighing approximately 0.5 to 3 kilograms.

Suitable Applications

-

Industrial Automation: Ideal for real-time data collection, monitoring, and control.

-

Military and Aerospace: Designed for missions that require high reliability and real-time performance.

-

Distributed Networks: Supports data sharing and real-time communication across multi-node distributed networks.

Additional Features

-

Fiber Optic Connectivity: Supports multimode fiber optic connections up to 300 meters, and single-mode fiber optic connections up to 10 kilometers.

-

Environmental Adaptability: Operating temperature range from -40°C to +85°C, storage temperature range from -40°C to +85°C, with humidity tolerance between 5% and 95%.

-

Operating System Compatibility: Compatible with multiple operating systems, including Windows, Linux, and VxWorks.

Conclusion

The GE VMIVME-5565-010000 332-015565-010000P is a highly reliable and high-performance embedded module, widely used in industrial automation, military, and aerospace applications. Its unique reflective memory technology and high-speed data transfer capabilities make it an ideal choice for complex distributed systems.

Annual hot selling advantage products:

ABB PM665、ABB S-073N、ABB S-123H 3BHB030479R0512

First hand source, affordable price. Spot inventory!

•Shipping Port: Xiamen

•Ship to you via Fedex/DHL/TNT/UPS/EMS

•Package: Original packing with cartons

GE Hot Selling models

What is a DCS?

A Distributed Control System (DCS) is a sophisticated, computer-based control system designed to automate, monitor, and manage complex industrial processes. It is widely used in large-scale industrial facilities such as refineries, power plants, chemical plants, and paper mills, where precision, reliability, and scalability are critical.

How Does a DCS Work?

A DCS is composed of several interconnected components that work seamlessly to ensure efficient process control. Here’s a breakdown of its key elements:

- Controllers:

These are the “brains” of the system. Controllers receive data from sensors, process it using pre-programmed logic, and send output signals to actuators to maintain optimal process conditions. - Sensors:

Sensors act as the “eyes and ears” of the system, measuring critical physical parameters such as temperature, pressure, flow rate, and level. This real-time data is essential for accurate control. - Actuators:

Actuators are the “muscles” of the system. They execute physical actions based on controller commands, such as opening/closing valves, starting/stopping motors, or adjusting dampers. - Operator Stations:

These serve as the human-machine interface (HMI), allowing operators to monitor the process, adjust setpoints, and troubleshoot issues. Modern DCS systems often feature intuitive graphical interfaces for ease of use. - Communication Network:

The backbone of the DCS, this network connects all components, enabling seamless data exchange and coordination. It ensures that every part of the system works in harmony, even across large industrial sites.

Why is a DCS Important?

- Centralized Control with Distributed Execution: A DCS allows for centralized monitoring while distributing control functions across multiple controllers, reducing the risk of system-wide failures.

- Scalability: It can easily expand to accommodate growing operational needs.

- Reliability: Redundant systems and fail-safes ensure continuous operation, even in critical environments.

- Efficiency: Optimizes processes, reduces waste, and improves overall productivity.

There are no reviews yet.