Product Description

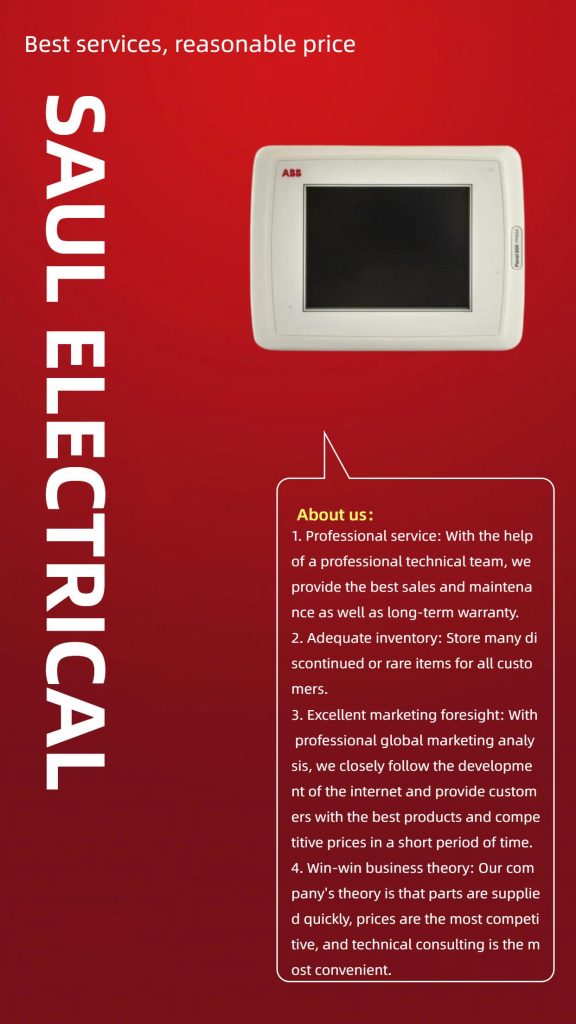

ABB PP825A is a 10.1-inch color touch panel that is part of the ABB Panel 800 family. It is a high-performance, user-friendly HMI (human-machine interface) that can be used to monitor and control a variety of industrial processes.

Product Parameters

- Display size: 10.1 inches

- Display type: TFT LCD

- Display resolution: 1024 x 600 pixels

- Touchscreen type: Resistive

- Processor: 1 GHz ARM Cortex-A9

- Memory: 512 MB RAM, 4 GB flash storage

- Communication ports: 1 x Ethernet, 1 x USB host, 1 x USB mini-B

- Power supply: 12-24 VDC

Usage Method

The ABB PP825A touch panel can be programmed using the ABB Automation Builder software. Automation Builder is a powerful and flexible software platform that allows users to create and configure HMIs, PLCs, and other automation devices.

To program the ABB PP825A touch panel, users can create graphical screens that contain the desired elements, such as buttons, text boxes, and trend charts. Users can also assign actions to these elements, such as turning on a motor or changing a setpoint.

Once the touch panel is programmed, it can be connected to a PLC or other automation device and used to monitor and control the process.

Product Application

The ABB PP825A touch panel can be used in a variety of industrial applications, including:

- Manufacturing

- Food and beverage

- Oil and gas

- Power generation and distribution

- Water and wastewater treatment

- Building automation

Here are some specific examples of how the ABB PP825A touch panel can be used:

- In a manufacturing plant, the ABB PP825A touch panel can be used to monitor and control a production line. The touch panel can be used to display real-time production data, start and stop machines, and adjust process parameters.

- In a food and beverage plant, the ABB PP825A touch panel can be used to control the temperature and humidity of a fermentation chamber. The touch panel can also be used to monitor the quality of the product and to record data for compliance purposes.

- In an oil and gas refinery, the ABB PP825A touch panel can be used to monitor and control the flow of oil and gas through the refinery. The touch panel can also be used to alarm operators of any problems that occur.

- In a power plant, the ABB PP825A touch panel can be used to monitor and control the generation and distribution of electricity. The touch panel can also be used to alarm operators of any problems that occur.

- In a water treatment plant, the ABB PP825A touch panel can be used to monitor and control the treatment process. The touch panel can also be used to alarm operators of any problems that occur.

- In a building automation system, the ABB PP825A touch panel can be used to control the heating, ventilation, and air conditioning (HVAC) system, the lighting system, and the security system.

The ABB PP825A touch panel is a versatile and powerful HMI that can be used in a wide range of industrial applications.

We can respond globally and deliver quickly.

A strong supply network ensures that when manufacturers’ equipment malfunctions or stops

Able to respond promptly and provide assistance

Provide multilingual services

Original accessories from various brands

One stop procurement for enterprise customers

Original parts from various brands, including leading manufacturers, with reliable quality and a complete range.

PP826 3BSE042244R1

PP825 3BSE042240R1

PP825A 3BSE042240R3

Panel 800

Range of user-friendly, intuitive and ergonomic operator panels for process automation systems

The Panel 800 version 6.2 family comprises of user-friendly, intuitive and ergonomic operator panels that combine slim, space-saving dimensions with a comprehensive range of advanced functions. Panel 800 Version 6 comprises of Standard, black and rugged panels that boast of more interfacing options, speed and brilliant displays.

Designed to make process automation easy, all 11 panels are equipped with advanced functionality for process and equipment control, maneuvered by touching the LCD display. Combined with market-leading performance and stunning graphical ability, Panel 800 erodes the line between ordinary Operator Panels and PC-based HMIs. All panels are configured using ABB’s Panel Builder tool that contains all basic functions needed in an application. The functions are tested and developed with customer needs and preferences in focus.

Easy to use

A fully deployable HMI with comprehensive and integrated templates and libraries for every conceivable process. The Panel Builder tool, with familiar Microsoft® Windows® environment along with multiple language support results in remarkably quick, easy and efficient engineering.

State-of-the-arts graphics

Vector-based, high-resolution graphics in TFL/LED display, with icon-based interface navigation and control.

Robust and reliable technology

Panel 800 is constructed in a strong yet lightweight die-cast, powder-coated aluminum housing. IP65/IP66 front casing withstands wet, dusty and demanding environments. Operating temperatures ranging between -30oC to 70oC with maximum 95% humidity.

Truly open platform

Built on open architecture and technologies that accompany the .NET framework, these panels are capable of multi-brand controller connectivity. A multitude of connection options are available for local communication, expansion, remote access and more.

There are no reviews yet.